|

Capacity (BPD) |

Power (Kw/d) |

Fabrication Period (month) |

Area (Acre) |

Skid Number |

Weight (Ton) |

|

|

MR10 |

1000 |

150 |

5 |

1 |

5 |

120 |

|

MR30 |

3000 |

200 |

5 |

2 |

7 |

160 |

|

MR50 |

5000 |

275 |

6 |

2 |

8 |

200 |

|

MR100 |

10000 |

350 |

6 |

3 |

11 |

375 |

|

EPC Scope of Work |

||||

|

No. |

Item |

|

By PCC |

By End-user |

|

1 |

Feasibility Study |

Engineering |

|

√ |

|

2 |

Basic Design |

√ |

|

|

|

3 |

Detail Design |

√ |

|

|

|

4 |

Budgeted Deliverables |

√ |

|

|

|

5 |

local government approval and supervision |

|

√ |

|

|

6 |

Purchase Requisitions |

√ |

|

|

|

7 |

Parsed MTO |

Procurement |

√ |

|

|

8 |

Purchase Order |

√ |

|

|

|

9 |

Transportation & Logistics |

√ |

|

|

|

10 |

Release to Construction |

√ |

|

|

|

11 |

Contracts |

√ |

|

|

|

12 |

General Const.Plan |

Construction |

√ |

|

|

13 |

Civil work |

|

√ |

|

|

14 |

Piping |

√ |

|

|

|

15 |

System Turn-over |

√ |

|

|

|

16 |

Start-up & Commissioning |

√ |

|

|

|

17 |

Performance Run |

√ |

|

|

|

18 |

Turn-Over to end-user |

√ |

|

|

|

|

||||

|

OSBL & ISBL Scope of Work |

|

|

|

|

|

No. |

Item |

|

By PCC |

By End-user |

|

1 |

10000 BPD CDU+VDU |

Inside Battery Limits |

√ |

|

|

2 |

Tank Farm |

Outside Battery Limits |

|

√ |

|

3 |

Water Supply and Drainage System |

|

√ |

|

|

4 |

Power Supply and Telecommunication System |

√ |

|

|

|

5 |

System Pipelines |

√ |

|

|

|

6 |

Central Control Room |

|

√ |

|

|

7 |

Wharf and Berth |

|

√ |

|

|

8 |

Vehicle Load-Unload Facility |

√ |

|

|

|

9 |

Flare System |

√ |

|

|

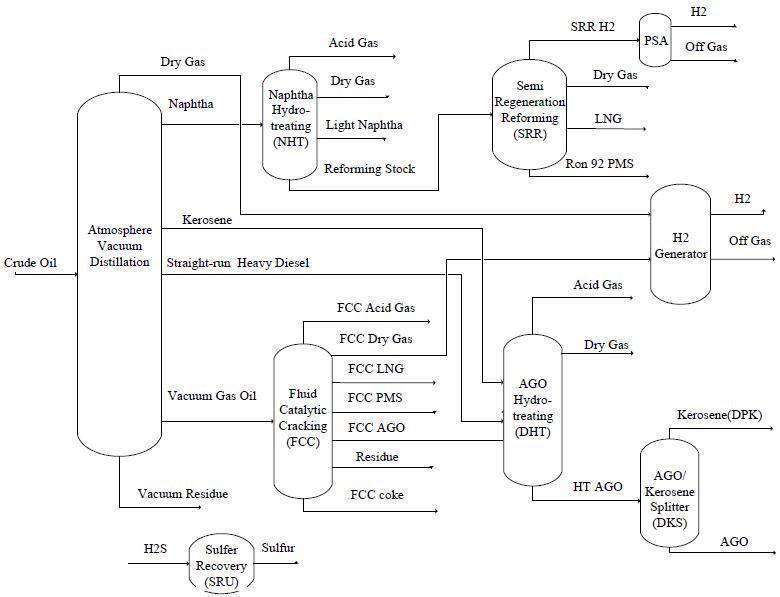

Take one of Nigeria crude oil with API Gravity 36.25 and mercaptan sulfur 1.3ppm for example.

we will contact you within 24 hours.