Green Field Refinery

June 5, 2017This unit is applicable to wellhead natural gas pretreatment, including dehydration, hydrocarbon recovery, compression, storage transportation and pressure regulation project, ...view

June 5, 2017This unit is applicable to wellhead natural gas pretreatment, including dehydration, hydrocarbon recovery, compression, storage transportation and pressure regulation project, ...view June 5, 2017Process Routes and Solution of LPG PlantAccording to the gas source and usages, we design to remove the heavy hydrocarbon in feed gas, produce LPG and stable light hydrocarbon at the same time make dr...view

June 5, 2017Process Routes and Solution of LPG PlantAccording to the gas source and usages, we design to remove the heavy hydrocarbon in feed gas, produce LPG and stable light hydrocarbon at the same time make dr...view July 11, 2017Crude Oil Distillation Unit (CDU): is the first processing unit in virtually all oil refineries. The CDU distills the incoming crude oil into various fractions of different boiling ranges, each of whi...view

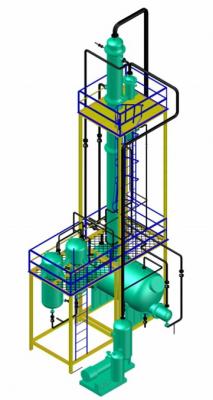

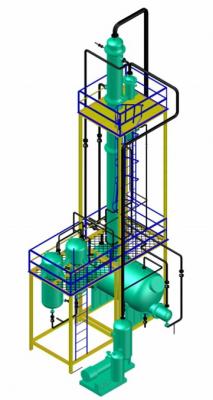

July 11, 2017Crude Oil Distillation Unit (CDU): is the first processing unit in virtually all oil refineries. The CDU distills the incoming crude oil into various fractions of different boiling ranges, each of whi...view June 5, 2017PCC's Modular Refineries are designed and fabricated in our manufacturing base located in Tianjin, China. As the name implies, all equipment is constructed in modules that are designed to be transport...view

June 5, 2017PCC's Modular Refineries are designed and fabricated in our manufacturing base located in Tianjin, China. As the name implies, all equipment is constructed in modules that are designed to be transport...view July 11, 2017Vacuum Distillation Unit (VDU): further distills the residue oil from the bottom of the crude oil distillation unit. The vacuum distillation is performed at a pressure well below atmospheric pressure.view

July 11, 2017Vacuum Distillation Unit (VDU): further distills the residue oil from the bottom of the crude oil distillation unit. The vacuum distillation is performed at a pressure well below atmospheric pressure.view June 5, 2017PCC has proven track record of providing comprehensive gas utilization solutions for onshore and offshore projects. Such solutions often ensure the implementation of innovative technologies packaged w...view

June 5, 2017PCC has proven track record of providing comprehensive gas utilization solutions for onshore and offshore projects. Such solutions often ensure the implementation of innovative technologies packaged w...view June 5, 2017Mini Oil Refinery is applicable to processing small capacity of crude oil from 200 bpd to 500 bpd. This package offers guidance on estimating oil refinery plant cost for budgeting purposes.view

June 5, 2017Mini Oil Refinery is applicable to processing small capacity of crude oil from 200 bpd to 500 bpd. This package offers guidance on estimating oil refinery plant cost for budgeting purposes.view June 5, 2017Rich methane gas meets with rich gas ethane reheated by cooling heat exchanger, this steam of gas flows through the CNG compressor to increase pressure to 25Mpag, CNG product can be o...view

June 5, 2017Rich methane gas meets with rich gas ethane reheated by cooling heat exchanger, this steam of gas flows through the CNG compressor to increase pressure to 25Mpag, CNG product can be o...view June 5, 2017Modular Oil Refinery is applicable to processing capacity of crude oil from 1000bpd to 10000bpd.view

June 5, 2017Modular Oil Refinery is applicable to processing capacity of crude oil from 1000bpd to 10000bpd.view June 19, 2017Gas after dehydration flows through cooling heat exchanger and R – 22 refrigerating machine into heavy hydrocarbon gas liquid separator. Rich methane gas rises from the gas liquid separator top and i...view

June 19, 2017Gas after dehydration flows through cooling heat exchanger and R – 22 refrigerating machine into heavy hydrocarbon gas liquid separator. Rich methane gas rises from the gas liquid separator top and i...view July 11, 2017Diesel Hydrotreating Unit (DHT): uses hydrogen to desulfurize the naphtha fraction from the crude oil distillation or other units within the refinery.view

July 11, 2017Diesel Hydrotreating Unit (DHT): uses hydrogen to desulfurize the naphtha fraction from the crude oil distillation or other units within the refinery.view June 19, 2017Hydroskimming Oil Refinery is applicable to processing capacity of crude oil from 15000bpd to 25000bpd, and obtain the max. yield various products.view

June 19, 2017Hydroskimming Oil Refinery is applicable to processing capacity of crude oil from 15000bpd to 25000bpd, and obtain the max. yield various products.view July 11, 2017Semi-regenerative Reforming (SRR): used to convert petroleum refinery naphtha distilled from crude oil (typically having low octane ratings) into high-octane liquid products called reformates, which a...view

July 11, 2017Semi-regenerative Reforming (SRR): used to convert petroleum refinery naphtha distilled from crude oil (typically having low octane ratings) into high-octane liquid products called reformates, which a...view December 15, 2017Importance of Recovering CO2 As the energy demand increases and the daily consumption of petrochemical energy grows in developing countries, how to ensure rapidly the stable energy supply while reduce...view

December 15, 2017Importance of Recovering CO2 As the energy demand increases and the daily consumption of petrochemical energy grows in developing countries, how to ensure rapidly the stable energy supply while reduce...view June 23, 2017Oil refining processes are the chemical engineering processes and other facilities used in petroleum refineries (also referred to as oil refineries) to transform crude oil into useful products such as...view

June 23, 2017Oil refining processes are the chemical engineering processes and other facilities used in petroleum refineries (also referred to as oil refineries) to transform crude oil into useful products such as...view July 11, 2017Fluid Catalytic Cracking Unit (FCC): under the action of heat and catalyst, upgrades the heavier, higher-boiling fractions from the crude oil distillation by converting them into lighter and lower boi...view

July 11, 2017Fluid Catalytic Cracking Unit (FCC): under the action of heat and catalyst, upgrades the heavier, higher-boiling fractions from the crude oil distillation by converting them into lighter and lower boi...view July 11, 2017Sulfur Recovery Unit (SRU): converts sulfur gas such as H2S into elemental sulfur, so as to convert waste into treasure and protect the environment.view

July 11, 2017Sulfur Recovery Unit (SRU): converts sulfur gas such as H2S into elemental sulfur, so as to convert waste into treasure and protect the environment.view July 11, 2017Isomerization Unit: converts linear molecules such as normal pentane into higher-octane branched molecules for blending into the end-product gasoline. Also used to convert linear normal butane into is...view

July 11, 2017Isomerization Unit: converts linear molecules such as normal pentane into higher-octane branched molecules for blending into the end-product gasoline. Also used to convert linear normal butane into is...view June 16, 2017Adopt differential pressure coupling double-effect energy-saving technologies, feedstock pump into two columns simultaneously, reduce 35% heat, and use APC advanced control method to realize full automatic control.view

June 16, 2017Adopt differential pressure coupling double-effect energy-saving technologies, feedstock pump into two columns simultaneously, reduce 35% heat, and use APC advanced control method to realize full automatic control.view June 16, 2017The owner requests the COD of wastewater containing oil fall from 4000ppm to below 200ppm. After our experiments and process simulation, the device can handle the COD below 100ppm.view

June 16, 2017The owner requests the COD of wastewater containing oil fall from 4000ppm to below 200ppm. After our experiments and process simulation, the device can handle the COD below 100ppm.view June 16, 2017The client provided the tail gas component and the local emission requirements. The discharge tail gas content is much lower than local emission standard This project was delivered within 45 days, finished installation and commissioning in 5 days.view

June 16, 2017The client provided the tail gas component and the local emission requirements. The discharge tail gas content is much lower than local emission standard This project was delivered within 45 days, finished installation and commissioning in 5 days.view June 16, 2017The owner is the largest pharmaceutical intermediates Cephems in China. The feed is acetone mixed gas. The client requested that the yield is 95%, the purity is above 90%, the tail gas VOC is below 80PPM (mg/m3). The purity of our experiment and process cview

June 16, 2017The owner is the largest pharmaceutical intermediates Cephems in China. The feed is acetone mixed gas. The client requested that the yield is 95%, the purity is above 90%, the tail gas VOC is below 80PPM (mg/m3). The purity of our experiment and process cview